A denture teeth mold guide is a reference tool used in prosthetic dentistry, showcasing various sizes, shapes, and shades of artificial teeth for precise denture fabrication.

1.1 What is a Denture Teeth Mold Guide?

A denture teeth mold guide is a reference tool used in prosthetic dentistry to showcase the shapes, sizes, and shades of artificial teeth available from manufacturers. It aids in selecting the most suitable teeth for denture fabrication, ensuring natural aesthetics and functional compatibility. The guide helps dental professionals match patient needs with appropriate tooth molds, streamlining the denture creation process.

1.2 Importance of Mold Guides in Denture Fabrication

Mold guides are essential in denture fabrication as they provide a standardized reference for selecting artificial teeth, ensuring proper aesthetics, and functional compatibility. They help dental professionals match tooth shapes, sizes, and shades to patient needs, enhancing accuracy and efficiency. By streamlining the selection process, mold guides contribute to better patient satisfaction and more precise denture outcomes, making them a critical tool in modern prosthetic dentistry.

Understanding Denture Teeth Mold Types

Denture teeth molds vary in shape, size, and aesthetics, offering options to suit diverse patient needs and preferences in prosthetic dentistry.

2.1 Anatomical vs. Non-Anatomical Teeth Molds

Anatomical molds mimic natural tooth anatomy, offering realistic aesthetics and functional occlusion, while non-anatomical molds are more standardized, focusing on simplicity and cost-effectiveness for basic prosthetics.

2.2 Mould Charts and Their Role in Tooth Selection

Mould charts are visual tools displaying manufacturers’ tooth shapes, sizes, and shades, aiding dentists in selecting appropriate denture teeth. They facilitate aesthetic and functional decisions, ensuring natural appearance and proper occlusion. Shade guides like Chromascop complement mould charts, helping match tooth color to patient preferences. Examples include Classic Ultra Value and Pearl effect teeth, offering diverse options for prosthetic needs.

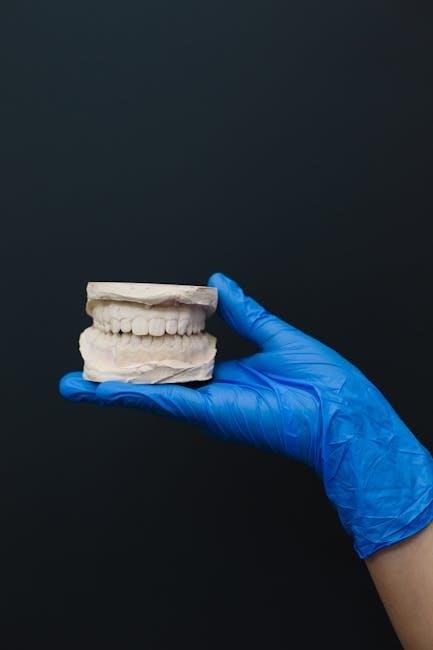

Denture Teeth Mold Fabrication Process

The process involves creating dental impressions, casting models, and fabricating molds to replicate natural teeth. Advanced materials ensure durability and aesthetics, with quality checks at each stage.

3.1 Steps in Creating a Denture Mold

Creating a denture mold begins with taking precise dental impressions using trays and impression materials. These impressions are then used to cast accurate models of the patient’s mouth. Next, the mold is fabricated to replicate the shape and alignment of natural teeth, ensuring proper fit and function. Quality checks and adjustments are made to achieve optimal results before finalizing the mold.

3.2 Dental Impressions and Model Creation

Dental impressions are taken using trays and impression materials to capture precise details of the patient’s mouth. These impressions are then used to create accurate models, typically made of plaster or resin. The models replicate the patient’s oral anatomy, ensuring the denture mold aligns correctly with the surrounding tissues. This step is crucial for achieving a natural fit and proper functionality in the final denture.

Selecting the Right Denture Teeth Mold

Selecting the right denture teeth mold involves considering factors like aesthetics, functionality, and patient preference. Mold charts and shade guides help in choosing the most suitable options.

4.1 Factors Influencing Tooth Selection

Factors influencing tooth selection include facial form, bite type, and patient preferences. The mold chart and shade guide help match teeth to the patient’s natural appearance. Jaw structure, aesthetics, and functional needs are also key considerations. Economic factors, such as budget and insurance coverage, may influence the choice of denture teeth molds.

4.2 Shade Guide and Aesthetic Considerations

The shade guide is essential for selecting denture teeth that match the patient’s natural tooth color and aesthetics. It ensures a harmonious smile by offering various shades and hues. Aesthetic considerations, such as tooth shape and arrangement, are tailored to the patient’s facial features and preferences, enhancing the overall appearance and satisfaction with the denture.

Types of Dentures and Their Molds

This section explores complete and partial dentures, focusing on their unique mold requirements and selection criteria for optimal fit and functionality.

5.1 Complete Dentures: Mold Requirements

Complete dentures require molds that accurately replicate the patient’s oral anatomy, ensuring proper fit and function. The mold guide must offer a variety of tooth shapes and sizes to match the patient’s facial structure and bite. Anatomical and non-anatomical tooth molds are considered, with precise alignment for optimal chewing and speaking ability. Aesthetic and functional criteria guide the selection process to ensure natural appearance and comfort.

5.2 Partial Dentures: Mold Selection Criteria

Partial denture molds must align with the patient’s remaining natural teeth, ensuring compatibility in size, shape, and shade. The mold guide should offer tooth options that blend seamlessly with existing dentition for aesthetic harmony. Functional considerations include support for chewing and speaking, while maintaining proper occlusal balance. The selected molds must also preserve surrounding tissue health and provide long-term durability.

Occlusion and Denture Teeth Molds

Occlusion ensures proper alignment of denture teeth for effective chewing and speaking. Matching the mold guide to the patient’s bite is crucial for optimal fit and function.

6.1 Role of Occlusion in Mold Design

Occlusion plays a critical role in denture mold design, ensuring proper alignment and contact between upper and lower teeth. This alignment is essential for chewing, speaking, and overall oral function. The mold guide helps select teeth that match the patient’s bite, ensuring natural aesthetics and functionality. Proper occlusion prevents uneven wear and enhances comfort, making it a cornerstone of successful denture design and patient satisfaction.

6.2 Functional Occlusal Angles in Mold Charts

Functional occlusal angles in mold charts are designed to ensure proper chewing and speaking functions. These angles, predetermined by manufacturers, guide the placement and alignment of artificial teeth. Mold charts offer various options to match individual patient needs, ensuring natural aesthetics and functionality. Proper alignment enhances denture performance, stability, and patient satisfaction, making occlusal angles a critical factor in successful denture fabrication and mold design.

Try-In and Fitting of Denture Molds

Wax molds are tried in the mouth to assess fit, aesthetics, and functionality. Adjustments are made during this stage to ensure optimal comfort and patient satisfaction.

7.1 Wax Mold Try-In Procedure

The wax mold try-in procedure involves placing temporary wax molds of the denture teeth in the patient’s mouth to assess fit, aesthetics, and functionality. This step ensures proper alignment, bite accuracy, and patient satisfaction before final fabrication. Adjustments to the molds are made based on the patient’s feedback and clinical evaluation, ensuring optimal comfort and appearance.

7.2 Adjustments and Final Fitting

After the wax mold try-in, adjustments are made to refine fit, occlusion, and aesthetics. The dentist evaluates the denture’s alignment, ensuring natural appearance and proper chewing function. Final fitting involves precise modifications, such as polishing or reshaping, to achieve optimal comfort and satisfaction. The denture is then processed and delivered, with a final check to confirm all adjustments meet the patient’s needs and expectations.

Advances in Digital Denture Mold Technology

Digital denture mold technology leverages CAD/CAM systems and 3D printing to create precise, customizable molds, enhancing accuracy and efficiency in denture fabrication compared to traditional methods.

8.1 CAD/CAM in Denture Mold Fabrication

CAD/CAM technology enables precise digital design and fabrication of denture molds, streamlining the process with high accuracy. It allows for customizable tooth selection and alignment, ensuring optimal fit and aesthetics. This method reduces human error and accelerates production, making it a cornerstone of modern denture fabrication.

8.2 3D Printing and Its Impact on Mold Guides

3D printing revolutionizes denture mold guides by enabling rapid prototyping and highly customizable designs. It allows for precise replication of complex tooth structures, improving fit and aesthetics. This technology enhances efficiency, reduces material waste, and offers patients more personalized solutions, making it a transformative tool in modern denture fabrication and mold guide development.

Maintenance and Aftercare of Denture Molds

Regular cleaning and proper storage are vital for maintaining denture molds. Use a soft brush and mild soap to clean, and avoid harsh chemicals. Store molds in a protective case to prevent damage. Regular dental check-ups ensure optimal fit and functionality.

9;1 Cleaning and Storage Tips

Proper cleaning involves using a soft brush and mild soap to remove plaque and debris. Avoid harsh chemicals or abrasive materials that may damage the mold. Rinse thoroughly and dry with a soft cloth. Store molds in a protective case to prevent warping or cracking. Regularly check for wear and tear, and replace if necessary. Cleanliness and safe storage ensure longevity and functionality.

9.2 Repair and Refurbishment Options

Minor cracks or wear on denture molds can often be repaired using specialized acrylic resins. For more extensive damage, professional refurbishment is recommended. Replace worn or discolored teeth to maintain aesthetics and functionality. Regular inspections by a dentist can prevent further deterioration. Refurbishment ensures a proper fit and extends the lifespan of the denture, avoiding the need for a completely new mold.

Cost Considerations for Denture Molds

Costs vary based on materials, complexity, and location. Custom molds are more expensive, while standard options are affordable. Prices range from $500 to $2,000 or more.

10.1 Budgeting for Custom Denture Molds

Budgeting for custom denture molds requires considering the quality of materials, design complexity, and dentist expertise. Custom molds are more expensive but offer superior fit and durability. Prices range from $500 to $2,000 or more, depending on specifics. Aesthetic preferences, like tooth shade and shape, also influence costs. Consulting with a dental professional helps create a realistic budget and ensures value for money.

10.2 Insurance Coverage and Financing Options

Insurance coverage for denture molds varies by provider and policy. Some plans cover partial costs, while others exclude custom molds. Financing options, such as payment plans or third-party lenders, can help manage expenses. Government programs or nonprofit organizations may assist eligible patients. Always check policy details and discuss financing options with your dentist to find affordable solutions for your denture needs.

Case Studies and Success Stories

Real-life examples demonstrate how custom denture molds have transformed patients’ lives, offering natural aesthetics and improved functionality. Patient feedback highlights satisfaction with comfort and confidence.

11.1 Real-Life Examples of Successful Denture Molds

Real-life examples highlight the transformative impact of custom denture molds. For instance, a 75-year-old woman regained her smile with anatomically accurate teeth, improving her speech and confidence. Another case involved a young professional whose partial denture mold restored chewing function and aesthetic appeal. These success stories demonstrate how precise mold selection and fabrication can meet individual needs effectively.

11.2 Patient Feedback on Denture Mold Satisfaction

Patients often report high satisfaction with custom denture molds, citing improved aesthetics, comfort, and functionality. Many appreciate how molds restore natural-looking smiles and enhance chewing efficiency. Feedback frequently highlights the impact on self-esteem, with patients feeling more confident in social and professional settings. The ability to tailor molds to individual needs ensures a personalized fit, leading to widespread positive experiences and improved quality of life.

Denture teeth mold guides are essential for precise fabrication, ensuring natural aesthetics and functionality. Emerging trends like digital denture technology and 3D printing promise enhanced accuracy and customization.

12.1 Summary of Key Points

Denture teeth mold guides are pivotal in fabricating natural-looking dentures, offering precise aesthetics and functionality. They streamline tooth selection, ensuring compatibility with patients’ oral anatomy. Modern advancements like CAD/CAM systems and 3D printing enhance customization and efficiency. Proper maintenance and aftercare extend mold longevity. The integration of digital technology promises future innovations, making denture fabrication more accessible and patient-specific.

12.2 Emerging Trends in Denture Mold Technology

Advancements in digital dentistry are revolutionizing mold technology, with CAD/CAM systems enabling precise, customizable designs. 3D printing is gaining traction for rapid prototyping and patient-specific molds. Biocompatible materials and AI-driven predictive tools for occlusal angles are also emerging. These innovations promise enhanced aesthetics, functionality, and efficiency, making denture fabrication more accessible and sustainable for future patients.